After more than a year of repeated tests and cooperation with seven other collaborators, the high-performance steel team of Shanghai University School of Materials successfully developed the world’s first 19.8-grade ultra-high-strength bolt known as the world’s strongest fastener.more importantly, Auto parts Made a fighter in the product, not afraid of any competitor’s attack. https://www.chinatianlong.com/

Through the optimization of materials and heat treatment process, the tensile strength of 16.8 and 19.8 grade bolts at room temperature meets 1600~1770MPa and 1900~2070MPa respectively.

The results of shear test (according to GJB 3376-1998) show that the shear force of grade 16.8 and grade 19.8 bolts reaches 97KN and 115KN respectively.

The tensile fatigue strength test at room temperature (according to GJB 3376-1998 and GJB715.30A-2002, the load ratio =0.1) shows that the developed fastener meets the fatigue life requirements (the average fatigue life is not less than 65,000 times, and the single fatigue life is not less than 45,000 times).

The results of delayed fracture resistance test (according to GJB 715.12-1990, the constant tensile stress was kept for 96 hours in atmospheric environment) showed that the bolt did not break during the test time, and no cracks were found on the bolt surface and thread after unloading. The comprehensive performance of the newly developed ultra-high strength bolt meets the service requirements.

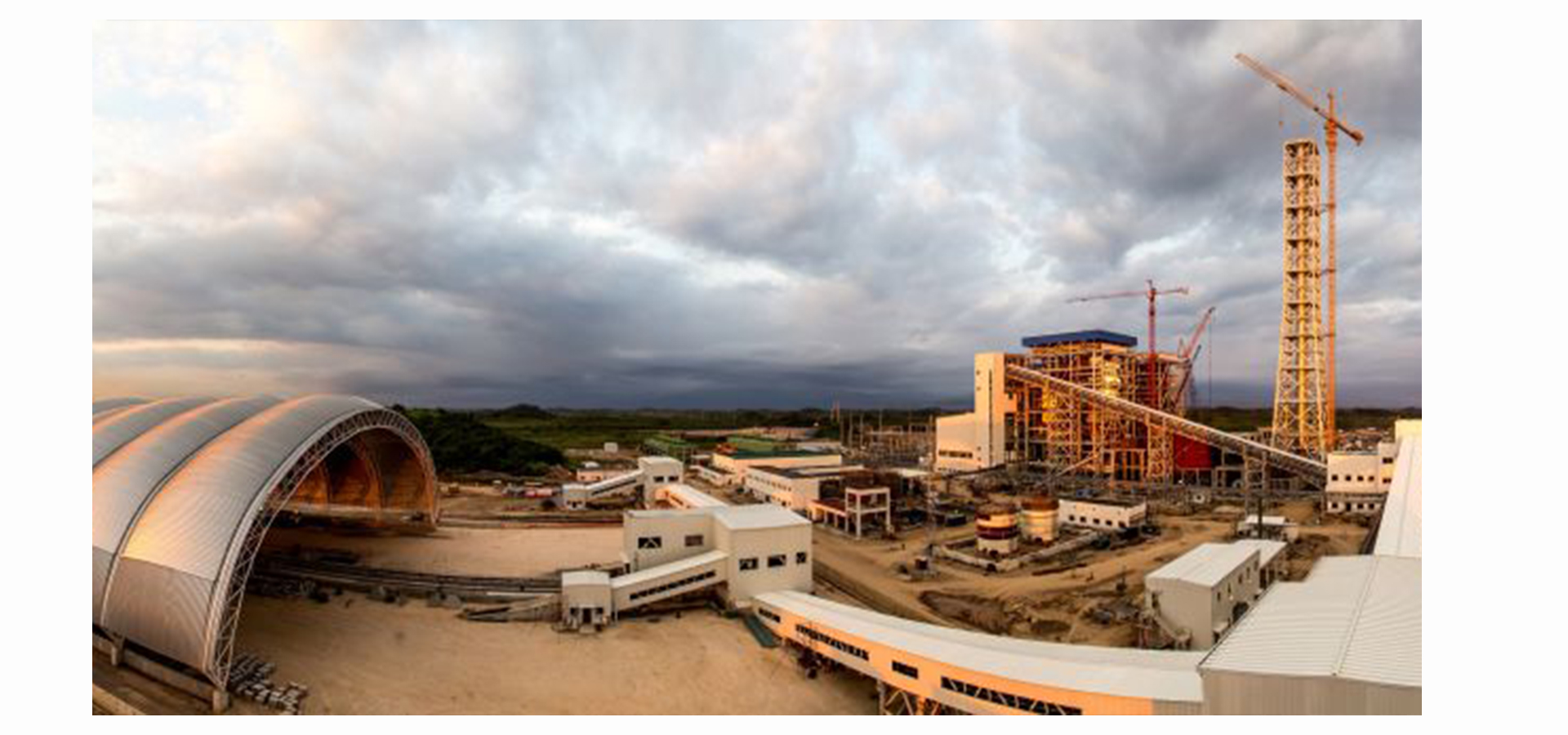

Class 16.8 and 19.8 fasteners in kind (specifications are MJ8〜1〜50)

Under the same clamping force, the ultra-high strength fastener can reduce its weight and increase the installation space by reducing its own size, so it can optimize the function and volume of the connected parts, so as to achieve the goal of overall weight reduction and performance optimization of the equipment.

So what is a high strength bolt? What is the strength of high-strength bolts? Sister Jin brought you here today to find out.

one

What is a high strength bolt?

High-Strength Friction Grip Bolt, literally translated as: high-strength friction preload bolt, abbreviated as HSFG. It can be seen that the high-strength bolt mentioned in Chinese construction is the abbreviation of high-strength friction pre-tightening bolt. In daily communication, only the words “Friction” and “Grip” are briefly mentioned, but it has caused many engineers and technicians to understand the basic definition of high-strength bolts, resulting in misunderstandings.

Myth 1:

Bolts with material grade over 8.8 are “high strength bolts”?

The core difference between high-strength bolts and ordinary bolts is not the strength of the materials used, but the form of stress. The essence is whether to apply pre-tightening force and use static friction to resist shear.

In fact, there are only two kinds of high-strength bolts (HSFG BOLT) mentioned in British Standard Specification and American Standard Specification (BS EN 14399/ASTM-A325&ASTM-490), while ordinary bolts include 4.6, 5.6, 8.8, 10.9, 12.9, etc. (BS 3692 11, Table 2) It can be seen that the strength of materials is not the key to distinguish high-strength bolts from ordinary bolts.

2?

Where is the strength of high-strength bolts?

According to GB50017, calculate the tensile and shear strength of a single ordinary bolt (Class B) with Grade 8.8 and a high-strength bolt with Grade 8.8.

Through calculation, we can see that the design values of tensile strength and shear strength of ordinary bolts are higher than those of high-strength bolts under the same grade.

So where is the “strength” of high-strength bolts?

In order to answer this question, it is necessary to study the law of elastic-plastic deformation of two kinds of bolts from the design working state, and understand the limit state of design failure.

Stress-strain curves of ordinary bolts and high-strength bolts under working conditions

Limit state of design failure

Ordinary bolt: the screw itself has plastic deformation exceeding the design allowable, and the screw is sheared.

For ordinary bolted connections, there will be relative slip between the connecting plates before they begin to bear shear force, and then the bolt rod will contact with the connecting plates, which will cause elastic-plastic deformation and bear shear force.

High-strength bolt: The static friction between the effective friction surfaces is overcome, and the two steel plates are relatively displaced, which is considered as failure in design.

When high-strength bolts are connected, the friction bears the shear force first. When the load increases to the point where the friction force is not enough to resist the shear force, the static friction force is overcome and the connecting plates slide relatively (limit state). However, although it is damaged at this time, the bolt rod is in contact with the connecting plate, and it can still bear the shear force by using its own elastic-plastic deformation.

Myth 2:

High bearing capacity is high strength bolt?

From the calculation of a single bolt, it can be seen that the design strength of high-strength bolt in tension and shear is lower than that of ordinary bolt. The essence of its high strength is that during normal operation, the joint is not allowed to slip, that is, the elastic-plastic deformation is small and the joint stiffness is large.

It can be seen that the joints designed with high-strength bolts may not necessarily save the number of bolts under the given design node load, but they have small deformation, high stiffness and high safety reserve. It is suitable for the main beam, and other positions that require greater joint stiffness, which conforms to the basic seismic design principle of “strong joints and weak members”.

The strength of high-strength bolts lies not in the design value of their own bearing capacity, but in the high stiffness, high safety and strong damage resistance of their designed joints.

three

Comparison between high strength bolts and ordinary bolts

Ordinary bolts and high-strength bolts have great differences in construction inspection methods because of their different design stress principles.

The mechanical performance requirements of ordinary bolts of the same grade are slightly higher than those of high-strength bolts, but high-strength bolts have one more acceptance requirement for impact work than ordinary bolts.

The marking of ordinary bolts and high-strength bolts is the basic method to identify bolts of the same grade on site. Because the values of torque calculation for high-strength bolts in British and American standards are different, it is necessary to identify the bolts of the two standards.

Ordinary bolts are about 70% of the price of high-strength bolts. Combined with the comparison of their acceptance requirements, it can be concluded that the premium part should be to ensure the impact energy (toughness) performance of materials.